- Description

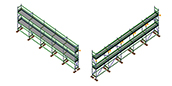

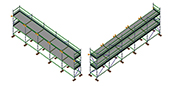

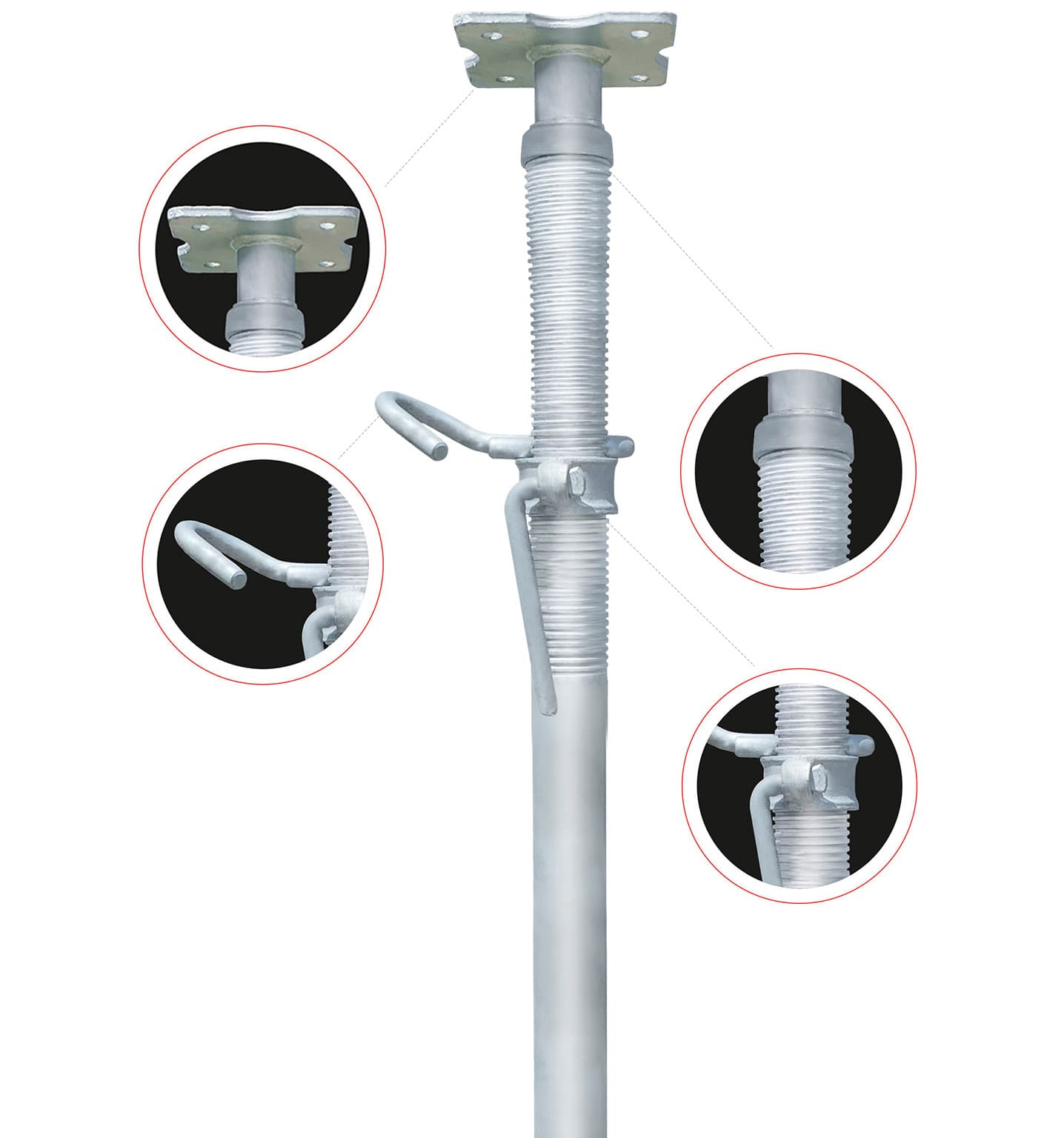

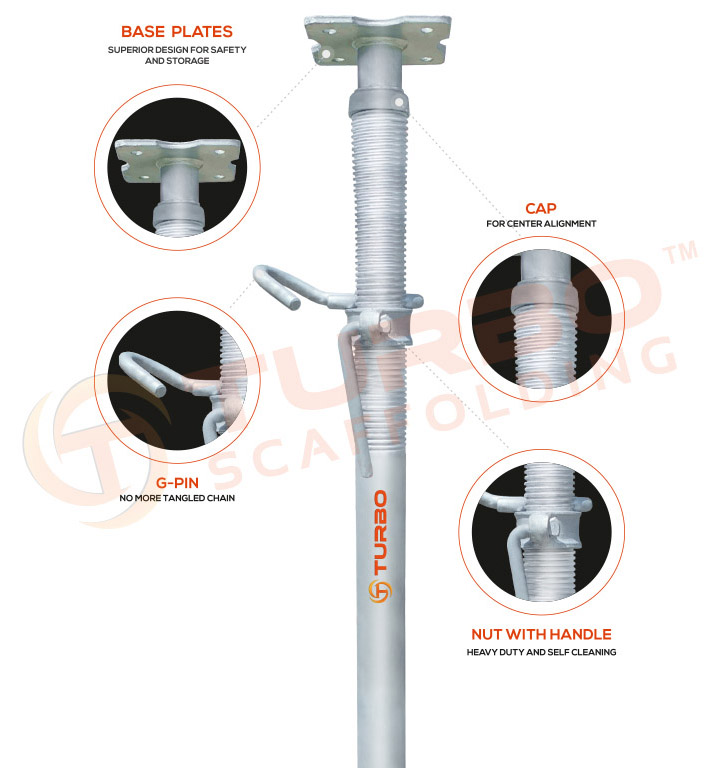

- Turbo Props are industrial grade Formwork Prop.

- Deal method of support for formwork, columns, beams and walls.

- Turbo Props are made with prime quality raw materials.

- Props nut that cleans it self

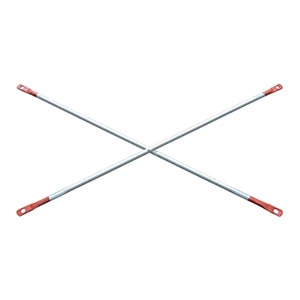

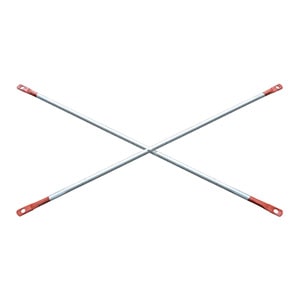

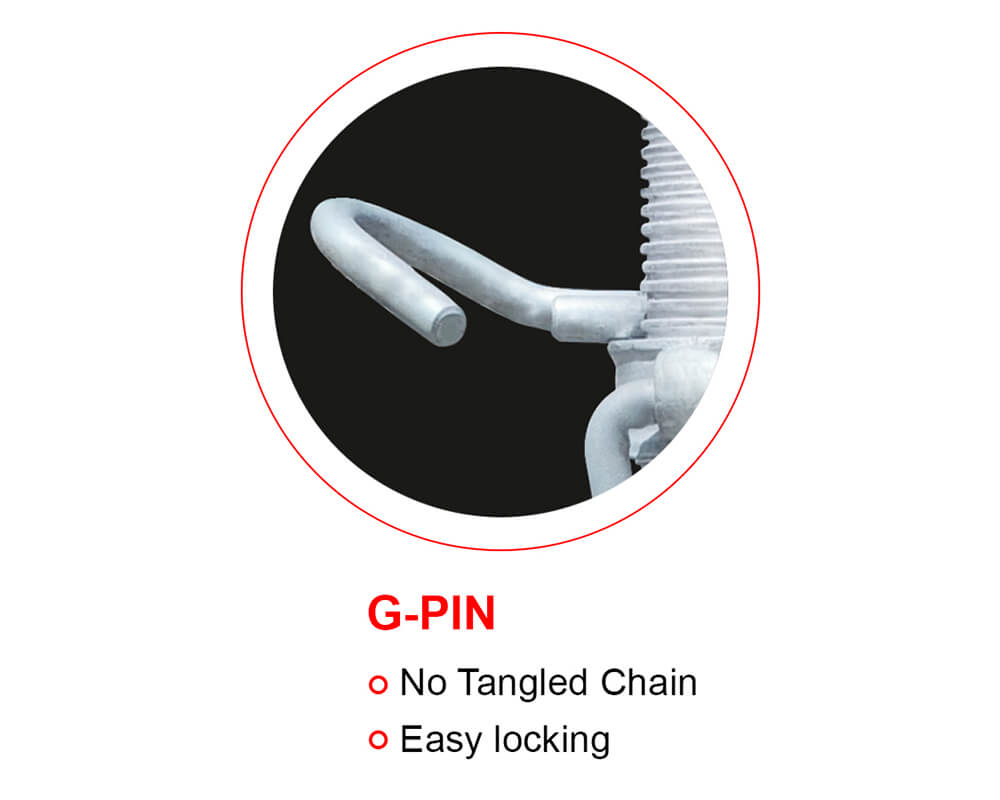

- All turbo props come complete with a locking G pin.

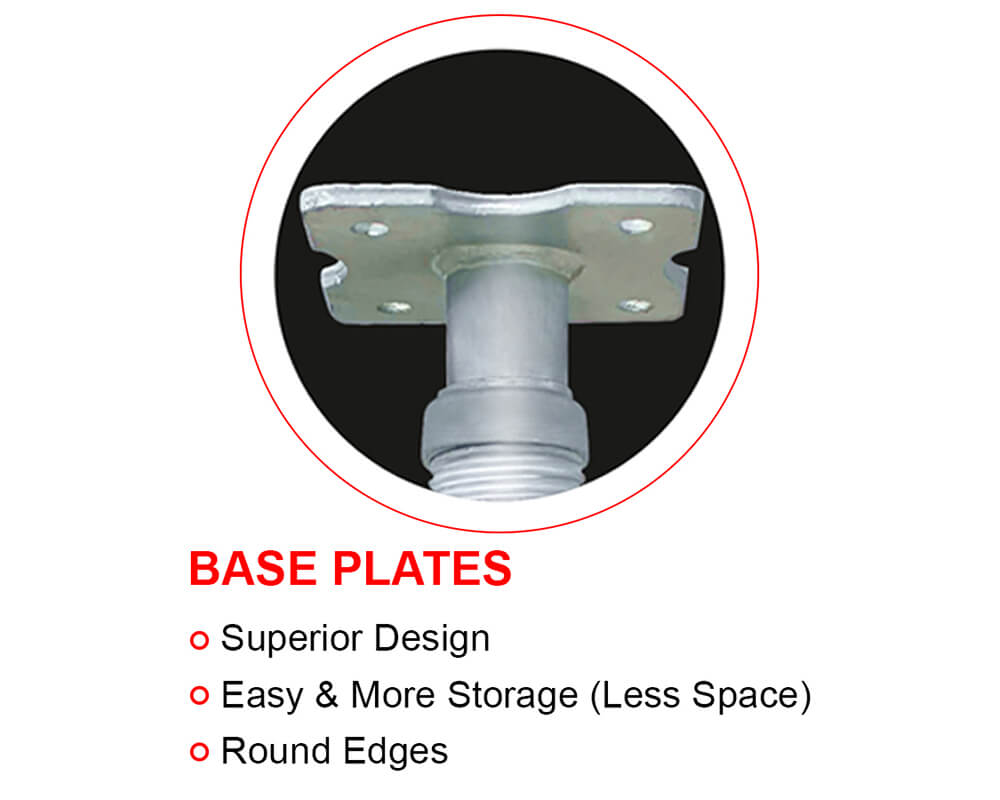

- Turbo props are designed for easy stacking.

- At welding and threading process are completed prior to the Prop being hot dipped.

Turbo Prop Specifications as per AS/NZS 3610:1995

| Code | Size (Close – Open) | Weight | WLL CLOSED | WLL OPENED |

|---|---|---|---|---|

| STUMPER | 0.45M x 0.70M | 9.31 kg | 51KN | 46.2KN |

| 00 | 0.69m x 1.16m | 10.75 kg | 40KN | 30KN |

| 0 | 1.07m x 1.82m | 14.41 kg | 26KN | 19KN |

| 1 | 1.60M x 2.80M | 20.78 kg | 24KN | 13KN |

| 2 | 1.98m x 3.35m | 21.83 kg | 24KN | 13KN |

| 3 | 2.59m x 3.95m | 24.61 kg | 21KN | 13KN |

| 4 | 3.2m x 4.87m | 29.54 kg | 18KN | 7KN |

Acrow Props for Sale

If you’re looking to buy acrow props in Sydney, Melbourne, Brisbane or Perth we have what you need. Turbo has a range of Acrow props for sale in all City locations.

Turbo Scaffolding’s Acrow Props are made with Prime Quality Raw materials and then hot-dipped galvanized at the completion of manufacture. All welding and threading processes are completed prior to the Prop being hot dipped, meaning that all surfaces that are exposed to the environment are fully protected by this process. All components including the inner & outer tube, base & head plates and threads are completely galvanised.

By utilising this technique, instead of the cheaper, faster zinc spraying of welding joints and threads, we can guarantee a no rust product with limited maintenance over our competitors.

If you need to buy acrow props in Sydney, Melbourne, Brisbane or Perth in time for your next build, we have a range of acrow props for sale on hand in our warehouse locations.