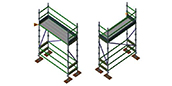

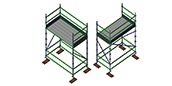

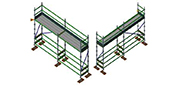

High-quality Scaffold Fittings and Accessories for Increased Safety

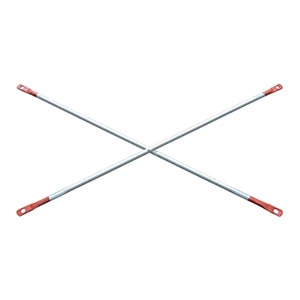

Scaffold fittings and accessories are indispensable essentials within the construction sector, facilitating the establishment and fortification of scaffolding structures. Crucial parts, such as couplers, clamps, swivels, and adjustable props, guarantee scaffolds’ stability, security, and safety during construction work.

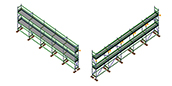

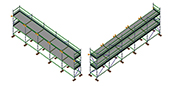

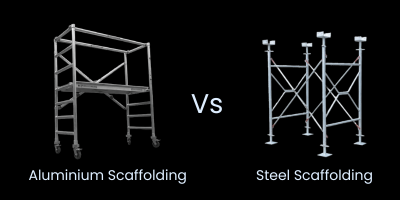

Scaffold Fittings Form the Foundational Framework

Scaffold fittings serve as the backbone, ensuring…