Click to call

- Sydney: 02 9725 5233

- Melbourne: 03 9357 6388

- Brisbane: 07 3034 1535

- Perth: 08 9410 0213

- Home

- Why Turbo

- Products

-

Kwikstage

Scaffolding Products -

Kwikstage

Scaffolding Packages - Aluminium Mobile Towers

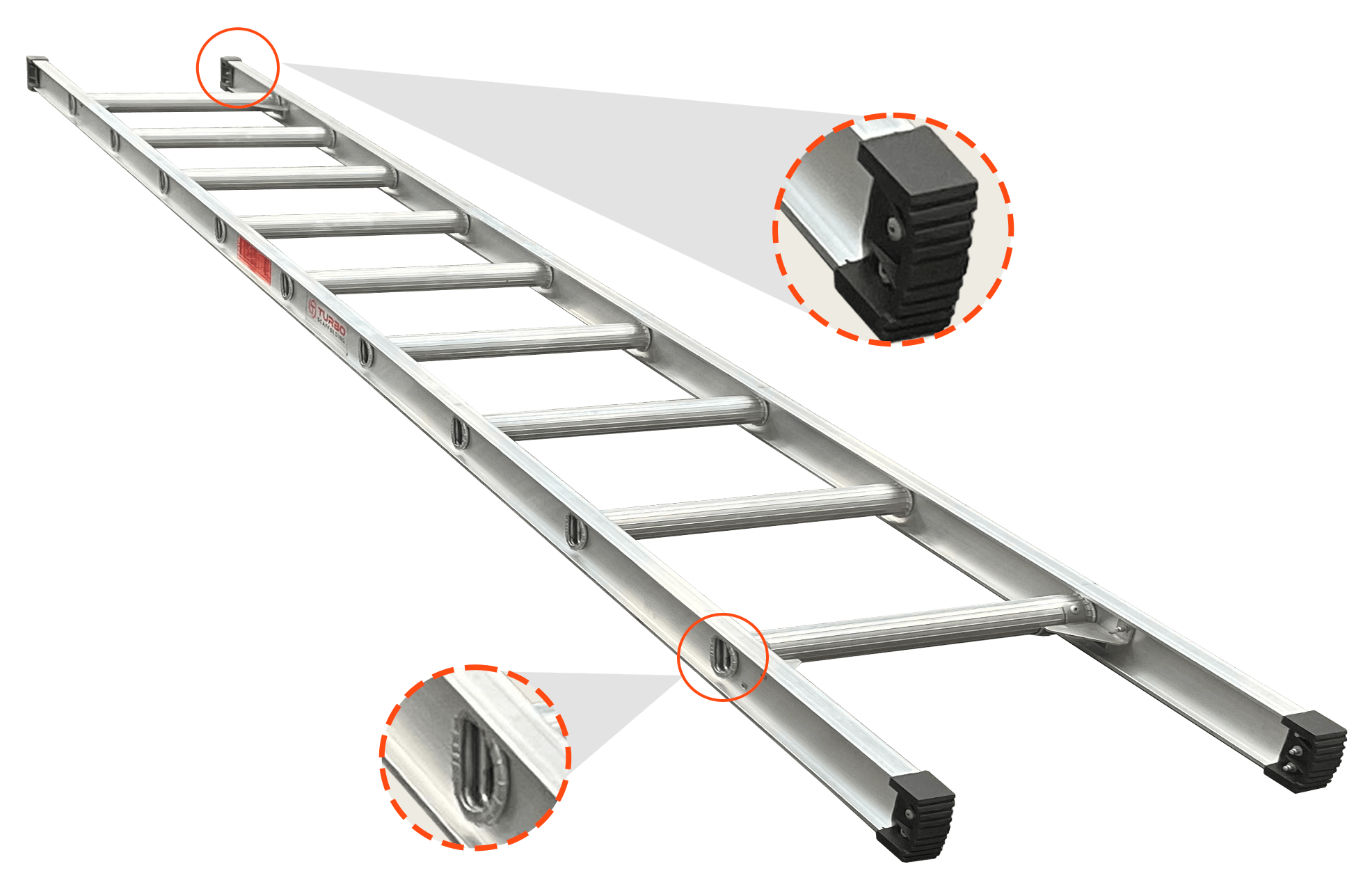

- Aluminium Access Ladder

- Turbo Props & Accessories

- Used Scaffolding

- Tools & Accessories

-

Aluminium Spandeck

Walkways Platform -

Retractable Loading

Bay Platforms -

Aluminium Erector

Scaffold Ladder

3 mtr Standing Height (5 mtr reach height)

Steel Scaffold Packages4 mtr Standing Height (6 mtr reach height)

Steel Scaffold PackagesSNAPPY/FOLDABLE TOWER2.3m - 2.6m Mobile Tower (Standing Height)3.1m - 3.4m Mobile Tower (Standing Height)3.9m - 4.2m Mobile Tower (Standing Height)4.7m - 5.0m Mobile Tower (Standing Height)5.5m - 5.8m Mobile Tower (Standing Height)6.3m - 6.6m Mobile Tower (Standing Height)1.9m - 2.2m Mobile Tower (Standing Height)2.7m - 3.0m Mobile Tower (Standing Height)3.5m - 3.8m Mobile Tower (Standing Height)4.3m - 4.6m Mobile Tower (Standing Height)5.1m - 5.4m Mobile Tower (Standing Height)5.9m - 6.2m Mobile Tower (Standing Height)Turbo PropsH Frame System -

Kwikstage

- Photo Gallery

- Finance

- Blog

- Contact Us

- Get a Quote

- Download brochures

New Year Sale! 20% OFF on All Aluminium Mobile Towers – Hurry up!

New Year Sale! 20% OFF on All Aluminium Mobile Towers – Hurry up!

New Year Sale! 20% OFF on All Aluminium Mobile Towers – Hurry up!

New Year Sale! 20% OFF on All Aluminium Mobile Towers – Hurry up!

Scaffold Maintenance

- Home

- Scaffold Maintenance

Recommendations for Scaffold Inspection and Maintenance

See: “Guidelines for scaffolding AS/NZS 4576:1995”

These recommendations will assist you in looking after your scaffold, ensuring it will safely do the job that it is specified to do and provide you with a long life of trouble-free use. Additionally, it informs you of your legal obligations when erecting and upon hiring.

To ensure the continued safety of your new scaffold, the “Guidelines for scaffolding” describes the procedure required to inspect and maintain your scaffold. The requirement for this procedure to be followed was re-iterated by WorkSafe in a special Communiqué in July 2005.

Scaffold Supply:

- Suppliers of scaffolding components are obliged under OH&S law to take all reasonably practicable measures to ensure that, upon delivery to site, they are serviceable. Thorough inspection regimes and between-hiring inspection and maintenance procedures should ensure the serviceability of the components when supplied.

During use:

- In addition to this procedure, scaffolders must visually inspect scaffolding components for faults when erecting, altering or dismantling scaffold.

Faults:

- Some of the things that you should look for when inspecting your scaffold include: checking the welds (ensuring there are no cracks), cleaning any deposits such as concrete, and testing to see that all bolts and pins move freely.

Isolation of faulty components:

- WorkSafe expects that, where a component fails or becomes in any way unserviceable during the erection process, the scaffolder will immediately remove it from the scaffold and replace it with a serviceable component. This should be done by clear marking or tagging, or placing in containers or areas that are clearly designated for the storage of rejected equipment.

Treatment of faulty scaffolding:

Once faulty or unserviceable components have been isolated, AS/NZS 4576 advises that they be treated in one of the following ways:

- Repaired (e.g. replacing bolts on couplers, replacing missing wedges on modular scaffolding, re-binding ends of timber planks, appropriate re-welding)

- Reduced in length (e.g. shortening of tube, planks or wire rope to remove defective ends)

- Downgraded (e.g. downgrading a scaffold plank for use as a soleplate, provided the fault does not adversely affect the performance of the soleplate)

- Scrapping.Any repair shall be made in accordance with sound engineering principles by a suitably qualified person.

A full description of what constitutes a fault (defect) and when an item requires scrapping is described in the ‘Guidelines for scaffolding’ Australian/New Zealand Standard 4576: 1995. Turbo scaffolding has a copy of these standards in the Despatch Office at all times. Please contact Turbo scaffolding if you require further information.

Quick links

Posts links

- Scaffolding Inspection and Maintenance Guide: What Ever...

- Common Scaffolding Misconceptions: Separating Fact from...

- Scaffolding on Uneven or Sloped Sites: What to Consider

- Essential Scaffolding Components for a Safe Worksite

- Turbo Scaffolding�s Durable Aluminium Systems Strengthe...

- The Ultimate Guide to Choosing Mobile Scaffolds for Sal...

- 5 Key Reasons Australian Contractors Prefer Mobile Scaffolds

Locations

Subscribe newsletter

Copyright © 2026 www.turboscaffolding.com.au All rights reserved.

Powered by :