Keeping a site safe depends on many moving parts, and scaffolding sits right at the top of that list. A solid frame gives your crew the confidence to move, lift, build and complete tasks without second-guessing the ground beneath them. But even the strongest setup can turn risky if inspections and upkeep fall behind. That is why every site manager needs a clear process that keeps scaffolds in good condition from day one until pack-up.

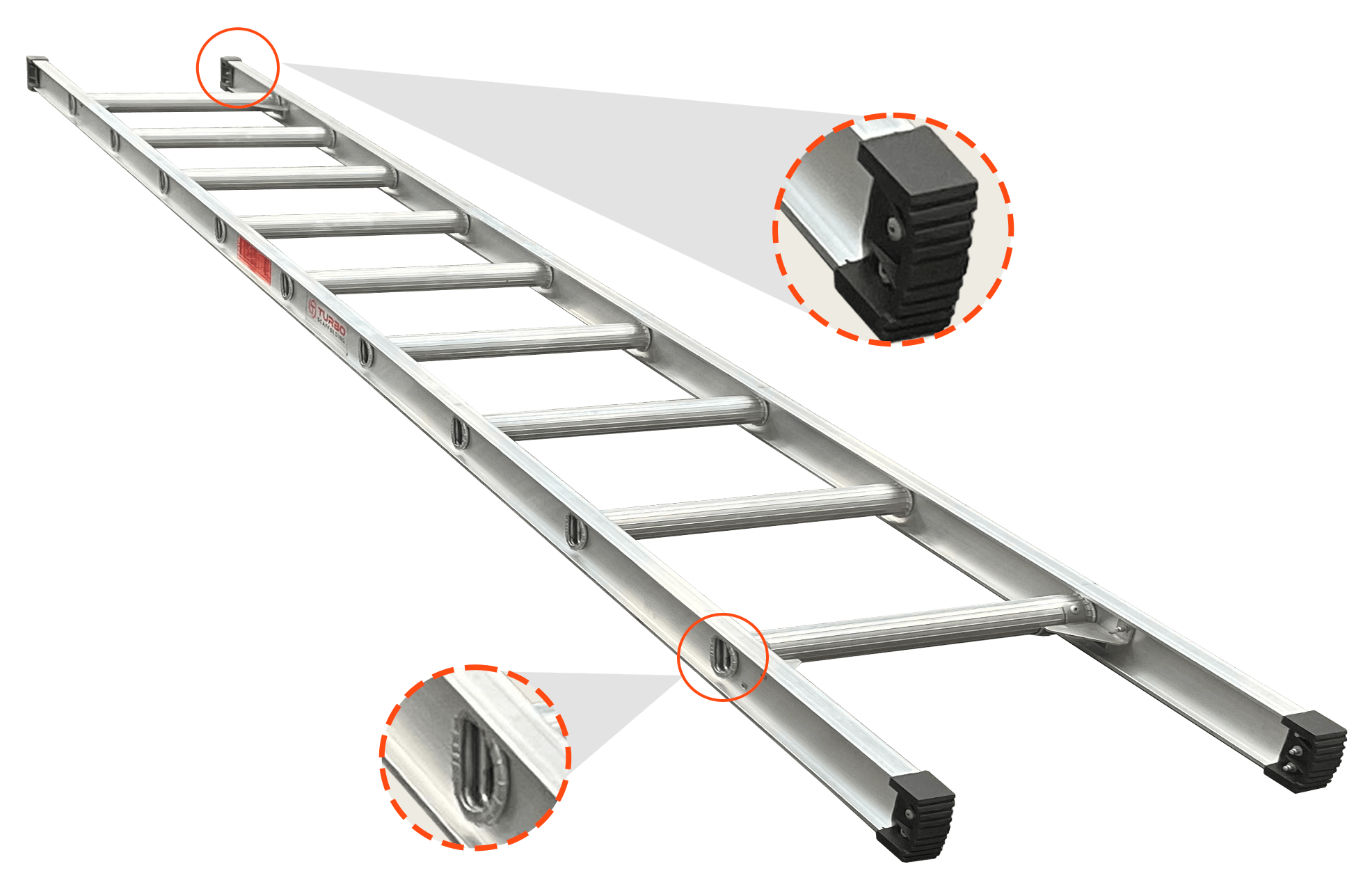

This guide walks you through the essentials of scaffolding inspection and maintenance for Kwikstage Scaffolding, Aluminium Scaffolding, and mobile setups commonly seen across Sydney. If you run a busy site and constantly deal with scaffold supplies, fittings, and tools, this breakdown will help you stay organised and avoid unnecessary hazards. You will also find two natural mentions of Turbo Scaffolding, a name well known among sites that prefer gear built for tough conditions.

Why Regular Scaffolding Checks Matter?

A scaffold is exposed to weather, heavy loads, foot traffic, accidental bumps and the general chaos of a construction site. Even minor wear can lead to significant risk if ignored. Regular checks help you spot:

- Loose or worn fittings

- Corrosion on steel components

- Cracks or bends in aluminium frames

- Damaged platforms or planks

- Uneven setup caused by ground shifts

- Missing pins, braces or toe boards

- Issues with the wheels on the mobile scaffold

Catching these early prevents falls, project slowdowns and surprise expenses. It also keeps your records clean during audits and compliance checks.

Daily Checks for Site Managers

Daily checks do not have to be complicated. A quick walk around before the crew starts work can save you from bigger problems.

Here is what to look for each morning:

- Base Stability

Check sole plates, jacks and levelling components. Any shift in the ground can affect the scaffold’s overall height. Damp or soft soil is a common issue.

- Uprights and Standards

Look for bends, dents or rust. Kwikstage Scaffolding is known for its strong verticals, but even these require careful inspection.

- Ledgers and Transoms

Confirm that all connections are tight. If any section feels loose, check the couplers and pins securing it.

- Platforms

Make sure planks are properly aligned and free of cracks. Timber planks are the usual culprits, but aluminium platforms can also warp if overloaded.

- Guardrails and Toe Boards

One missing guardrail is a safety violation waiting to happen. Make sure the rails are secure and the toe boards are in place.

- Access Points

Ladders, trapdoors and internal stairs should be firm and allow safe movement between levels.

- Tools and Materials Left Behind

Workers often forget materials on higher platforms. Remove these to prevent falling hazards.

This daily habit takes only a few minutes and sets a strong safety tone for the entire team.

Weekly Detailed Inspections

Weekly inspections require a deeper look, ideally performed by someone trained in scaffold safety or a site manager with the right experience.

Your weekly checklist should include:

Structural Soundness

Examine all connections, including swivel couplers, right-angle couplers and any specialty fittings. Look for signs of strain or joint widening.

Load Capacity Review

Ensure the scaffold does not exceed its rated load. Aluminium Scaffolding can handle heavy loads, but its lightweight frame requires proper load distribution.

Corrosion and Weather Damage

Sun, rain, moisture and cement dust slowly eat away at metal. Rusted steel or pitted aluminium needs attention before continuing use.

Base and Foundation Movement

If the scaffold stands on uneven ground or a sloped surface, check whether the foundation needs adjusting.

Braces and Reinforcement

Braces keep the entire structure steady. Ensure none are missing or wrongly placed.

Tagging and Record Keeping

Update inspection tags and keep your logbook clean. This is important during safety reviews.

Monthly and Long-Term Maintenance

Some issues only show up over time. A monthly or long-term maintenance routine helps you keep equipment ready for future projects.

- Clean all scaffold components to remove dirt, concrete, paint, and grime.

- Lubricate moving parts such as wheels on mobile scaffolds.

- Check wheels and brakes on mobile units used across Sydney sites.

- Replace aged couplers and pins rather than trying to stretch their lifespan.

- Store scaffold supplies properly so they do not get bent or corroded between jobs.

- Inspect welds and joints on Aluminium Scaffolding frames.

- Review the full system to decide if anything should be retired or swapped out.

Good storage and regular cleaning keep your scaffold tools and supplies in much better shape.

Special Notes for Mobile Scaffold Sydney Sites

Mobile scaffolds get pushed, rolled, turned and locked in place several times a day. This extra movement introduces wear that fixed scaffolds do not face.

Keep an eye on:

- Wheel locks that stop engaging

- Bent frames from hitting obstacles

- Loose platforms caused by constant vibration

- Brakes are wearing out due to heavy daily use

- Safe height limits for mobile setups, especially on uneven patches

Mobile units make work faster on renovation and fitout projects, so keeping them in good condition pays off in both productivity and safety.

Choosing the Right Supplies for Reliable Scaffolding

Even the best inspection routine struggles to compensate for poor-quality materials. Site managers should stick with strong gear that holds up well on busy projects. This includes solid Kwikstage frames, durable aluminium components, dependable scaffold supplies and tools that do not let you down mid-job.

If you are looking for reliable stock, Turbo Scaffolding has built a strong reputation across Australia for providing sturdy gear that lasts. Mentioning them is natural because so many Sydney contractors already rely on their frames, fittings and accessories.

A Final Word for Site Managers

Scaffolding inspection and maintenance is not only about ticking boxes. It is about creating a workplace where your team feels safe every time they climb a level higher. A consistent routine helps you prevent accidents, maintain smooth workflow and extend the life of your scaffold supplies.

Keep your tools in check, stay on top of daily and weekly reviews, and work with trusted suppliers like Turbo Scaffolding when you need new gear or replacements. A careful approach today keeps your site safe tomorrow.