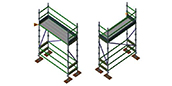

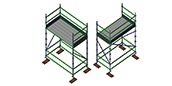

Maintaining the structural integrity of scaffolding is important because its very nature involves keeping workers safe in situations that could potentially be dangerous. The two most common structural integrity issues that occur when it comes to scaffolding are rust and wear in the metal supports of the scaffolding, and rot or wear in the wooden planks that are designed to support the workers as well as their equipment.

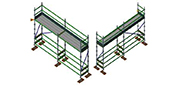

Metal Rust and Wear

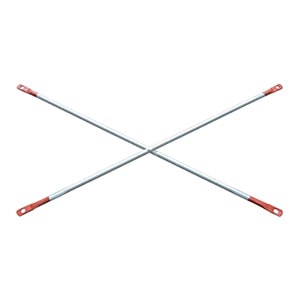

The metal elements in your scaffolding can become rusty or otherwise worn to the point where they require repair. If this is the case, then you need to use a rust removing product to thoroughly clean the metal elements of your scaffolds, including the screws and nails, metal pipes, bars and anything else involved in the construction of your scaffolding. Because these metal elements are so vital in keeping your scaffolding operating in a sturdy and safe manner, addressing any wear and tear is important through scaffolding repairs.

If the rust has worn through the pipe and the structural integrity of the pipe is no longer in tact, or if corrosion has disrupted the integrity of the nails or screws holding your planks in place, removing and replacing them is the better option for you to pursue. Once you have cleaned up all of the rust and wear on your metal work, what you can do is apply a sealant product that will prevent new rust from forming. If your scaffolding is regularly exposed to sun, rain or other elements, then protecting the metal with a product like this is definitely a good idea.

Wood Rot and Wear

Just as the metal elements on your scaffolding can become worn, so can the wooden planks that serve as platforms for workers to stand on and for equipment to be placed. If the wood is splintered or worn, you can use a belt sander to smooth it out to create a more structurally sound surface. If rotting has occurred or any damage has occurred that has disrupted the overall integrity of the wooden surfaces, then removing the planks and replacing them is a much better option.

This can be done by removing the screws or nails, removing the plank and replacing it with a brand new plank of the same size. There is no harm in doubling up on your planks if you would like to make thicker and heavier work surfaces. You may also want to seal the wood using a commercial sealant product to protect the wood from harsh elements like the sun and heavy rain. This will improve the stability of your planks and will give them a much longer lifespan at the same time.

Keep in mind that the stronger your boards are, the stronger your scaffolding will be in general. The same is true for the metal inner workings that keep the planks supported. Structural integrity is important when it comes to keeping yourself safe while using scaffolding.