When personnel wants to work at great heights, then scaffolding is the most economical means of gaining access. When we look around, we see some scaffolding systems painted and some galvanised.

Why are some scaffolding system painted while others galvanised?

Painted Scaffolding System

There are many reasons why scaffolding painted! The first and the main reason being painted scaffolding reduces rust and oxidisation. No matter what type of scaffolding used for the task at hand, all kinds of scaffolding ought to be structurally sound and secure. Scaffolding does weaken with time due to environmental considerations and general deterioration. When scaffolding painted, it gives a “casing” like finish that prevents the effects of water-on-metal contact, getting rid of the corrosion of the metal underneath. Although at times, scaffolding is personalised to showcase a company’s brand or corporate colours, it’s primarily painted for durability, security and dependability.

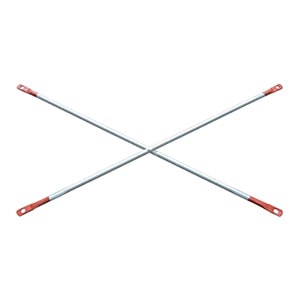

Scaffolding systems like Kwikstage and Cup-lock intended painted scaffolding types whereas tube and scaffold fittings galvanised.

Why Is Galvanised Scaffolding Priced Higher?

Though galvanised scaffolding is popular, it’s not common as painted systems, and that’s because of the differences in their costs. The common man would take it for granted that the system not having paint would be a cheaper purchase than the painted system. This assumption is not correct! Because scaffold’s made as fully galvanised systems pass through the added procedure, so they can be fully-galvanised and seal the metal from all corrosion and rust. The whole process of galvanisation is more time-consuming and thus, more expensive for the manufacturer and the customer.

If that’s the case, why take the trouble to buy galvanised scaffolding?

- Galvanised scaffolding systems last longer than painted systems, and also requires less maintenance and repairs.

- Galvanised scaffolding system is worth its asking price.

- Many offshore oil, gas and marine industries choose fully galvanised scaffolding system (Most popularly opting for fully-galvanised Cup-lock).

Galvanised Vs Painted Scaffolding

Galvanised and painted scaffolding systems both have their own merits and drawbacks with different costs and benefits.

- Painted systems most commonly used in the areas and environments that don’t experience harsh environmental conditions.

- When painted systems used, paint does break off and deteriorate through installation, use and dismantling of the scaffolding systems due to their characteristic. When that occurs, the part can become corroded, which gradually results in rust and a faulty part that need reconditioning, re-painting and re-testing for structural strength.

- Compared to painted scaffolding systems, fully galvanised scaffolding systems need far less of maintenance.

- Moreover, galvanised scaffold-systems hold a far higher lifespan. It can install in rough offshore environments without any risk of paint coming off to allow any corrosion and rust.

- The “added cost” paid on the purchase of galvanised scaffolding system is being saved on future maintenance costs.

- In contrast, painted scaffolding system can save for the short-term; however, you end up paying over the long-term for scaffolding maintenance and restoration.

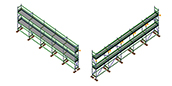

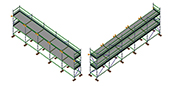

Kwikstage Scaffolding Packages

Kwikstage scaffold is a standard system made to render speedy assembly paired with highly flexible designs and enormous strength for all projects. Turbo Scaffolding provides two packages for painted and galvanised steel scaffold as follows:

- 3 Mtr standing height (5 mtr reach height).

- 4 Mtr standing height (6 mtr reach height).

With fast and handy assembly to no hassle disassembly, Turbo’s steel scaffolding packages made to suit most trades including roofers and painters. If you’re interested to know more — please visit the product page at Kwikstage Scaffolding Packages.

Final Words

Maintain a scaffolding system’s structural stability and enhance its lifespan by giving it a coat of paint or galvanising it entirely with a protective finish regardless of the scaffold system you choose or the finish you select.

- If your budget allows for long-term investment on a completely galvanised scaffold system, you can go for it as it will save you maintenance costs over long-term.

- In contrast, if your budget allows you to spend only on a painted system so that it can save you on the purchase costs for the short-term; bear in mind, it will inherit maintenance costs over the long-term.

Turbo Scaffolding has over 20 years of rock-solid experience in supplying high-quality scaffolding systems in Perth, Sydney Melbourne & Brisbane. We provide robust and durable scaffolding systems and fittings at unbeatable prices. Based out of Sydney, Turbo Scaffolding has vast warehouses in Sydney, Perth, Melbourne and Brisbane.