Scaffolding erection is a risky activity for those who actions the work, as well as for the general public. This instructional guide lays down steps that need to be followed by those who are involved with such kind of work. It is intended for those directly working in the scaffolding industry, as well as for planning supervisors, major contractors and clients. To guarantee scaffolding operations are safely carried out, below are the most important points that you will need to take into consideration.

1. Preparing the area

Foundations are very important as it is with any construction. Carrying out construction work on the uneven or unsteady ground is bad practice and can be very hazardous. The surface or ground must be as flat as possible and soil should be impenetrable and must be able to support the scaffold, even in wet weather.

2. Assuring safety is the priority

Never cut corners when structure’s safety is concerned. Ensure that structure is as safe as possible all the time, as well as the apparent PPE such as goggles, hard hats and gloves, are of good quality. Ladders, Handrails, Toe-boards and access gates must be furnished for every completed stage. If it’s not done accordingly, it will put you and your fellow workers’ lives at huge risk.

3. Safety of the general public

The public must be kept away from both the work area and an adequate area around it when the scaffolding operations are under way. Measures to ensure this will include:

- While operations are going on, a temporary pavement or street closure should be obtained.

- Integrate crash decks, tunnels and fans into a scaffold as soon as possible.

- Put up signs and barriers and divert the public away from the operations.

- Undertake operations in ‘serene’ hours i.e. early morning or at night or during the weekends.

- Take into account disabled persons require appropriate access along the pavements surrounded by scaffolding.

- Safely store scaffold clips and other loose materials on the scaffold and take care to not lift or lower materials over other site workers or the common public.

4. Inspection of scaffolds

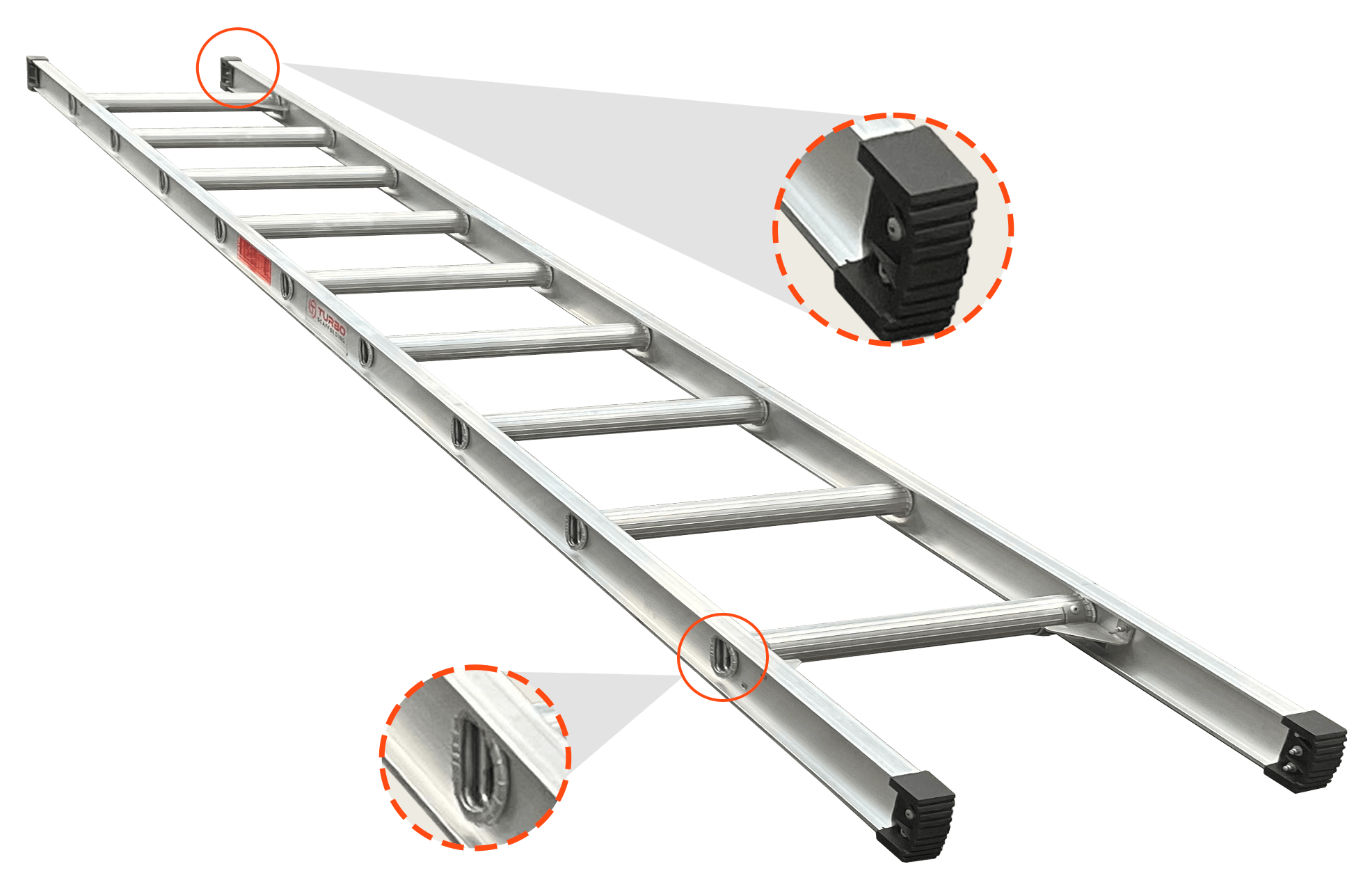

Prior to use, proper inspection of scaffolds should be carried out by the responsible personnel. A daily evaluation log should be maintained and produced, duly dated and signed each day and it should include things like undermining, corrosion and other wear and tear, as well as damaged braces and support. The condition of the scaffold planks, toe boards and handrails should be thoroughly inspected, along with signs of broken or damaged clamps, pins or braces.

5. Scaffolders working at height

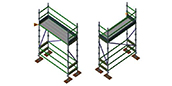

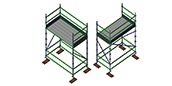

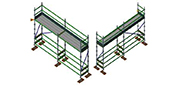

To prevent people from falls, scaffolders must follow safe work methods:

- When letting down or lifting materials, scaffolders should be clipped on or working within a handling platform, which is completely boarded with toe boards and double guardrails.

- As erection work advances, a minimum of three board working platforms along with a single guardrail is supplied.

- For one handed operation, safety harnesses to be put on all the time by the scaffolders and should be fitted with a 1.75m length lanyard and a 55mm opening scaffold hook or similar.

Where falls of four-metre or more are possible, harnesses must be clipped on to a secure point. The following minimum conditions need to be fulfilled for a secure anchorage point:

- As the work advances, the scaffold must be tied into a sound structure.

- Attachment can be made to a transom, ledger or transom supported by ledgers or a guardrail supported with load bearing couplers in the upper lift, fastened securely at both the ends by single-couplers.

- As the work advances, at least one bay of a scaffold must stay boarded out and this must be used for ladder access for the full scaffold height.

- At the time of erection process, safe ladder access must be integrated as early as possible for the scaffolders. And the most important thing, always buy standard quality scaffolding for safe work.

- Scaffolders must not be clambering up and down the scaffolds without fitting ladder access and safe working platforms should be furnished on each lift that’s being worked on.

6. Training and supervision

The most vital element in averting accidents on-site is the sound knowledge and training of scaffolders. Furthermore, never forget the significance of supervising the scaffolding contractor. Main contractors, clients and others who handle must take practical steps to ensure the work being performed on their site or premises is safely undertaken. Simple steps include the following:

- Verify the scaffolders training levels and who will be supervising them on-site.

- Supervising on-site to make sure scaffolders abide by appropriate safety standards.