Scaffolding and formwork are both an integral part of any construction project. Whether a construction project involves the creation of buildings, bridges, or other man-made structures, it is important to set up proper scaffolding and formwork to ensure a good finish, maintain the integrity of the structure, and make sure the process remains safe.

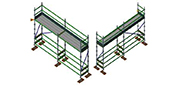

To make sure the formwork is capable of handling the load of the fluid concrete and other machinery or equipment that may be placed on it, all the calculations are done beforehand and verified before engaging in the process. In some scenarios, it is crucial to use scaffolding formwork to support the structure properly.

It is also necessary to prop and brac the formwork both horizontally and vertically to help it retain the shape until it is cured. Temporary formworks are removed once the concrete solidifies and gains the strength to support itself properly. However, sometimes, it may be left as permanent formwork in some cases as a finished feature.

Difference Between Formwork and Falsework

Formworks are structures that act as temporary or permanent mold for fluid concrete or similar materials so these can attain the desired shape. Essentially, formwork is designed to preserve the shape of the structure until it becomes self-supporting.

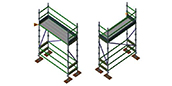

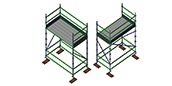

Normally, temporary structures such as scaffolding are created by construction workers so that they can access hard to reach places for doing construction work. However, scaffolding may be adapted to aid in formwork as well. Thus, the falsework is the temporary scaffolding created to support formwork required to construct buildings, elevated roadways, or bridges. Falsework is also known as scaffolding formwork.

Types of Materials Used in Formwork Systems

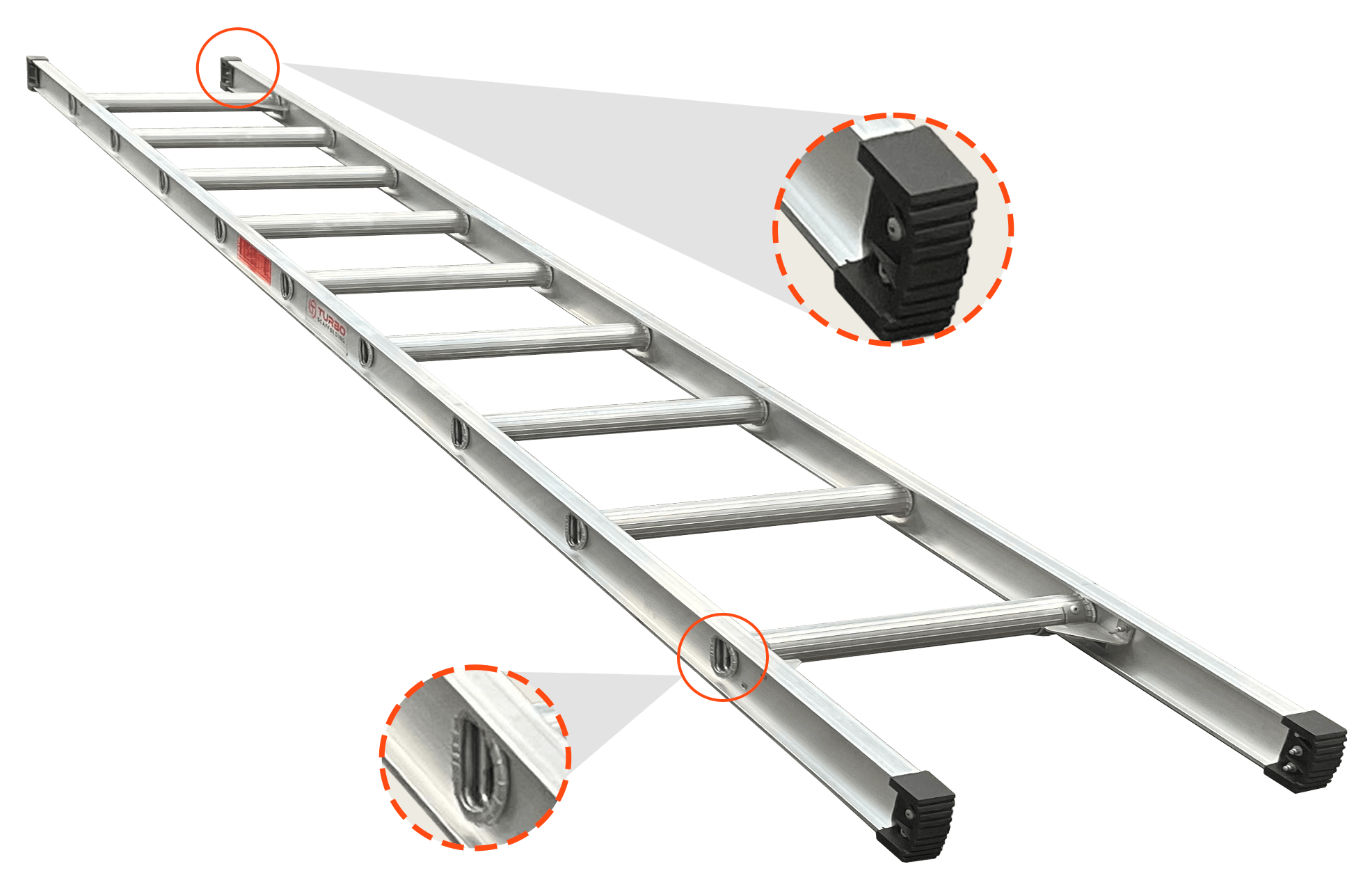

Common materials used to make formwork include steel, timber, plastic, and pre-formed panels made of aluminum. Timber or wooden shuttering is generally avoided except for smaller projects as it has a tendency to absorb water which can result in it becoming warped. This may reduce the quality of the final finish.

To achieve the highest quality concrete finish, a metal formwork system is utilised. These contain steel, plywood face, or good quality plastic. A combination of steel and aluminum forms may be used to increase the strength, lifespan, durability, and reusability.

How Turbo Scaffolding can Help you Make your Job Easier

It is essential to choose a good company for buying products that can aid in your construction projects. Otherwise, you may not receive high-quality products or the support that you need.

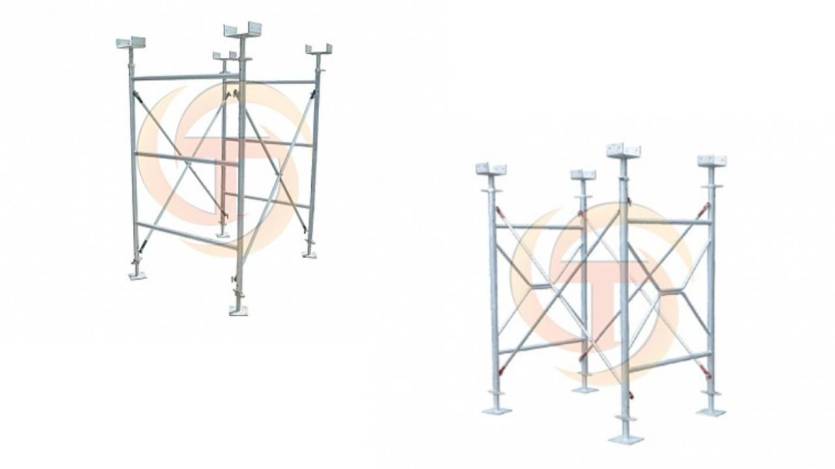

We are one of the largest companies that provide scaffolding formwork in Melbourne, Sydney, Perth, and Brisbane. You can purchase steel scaffolding formwork systems such as the H Frame system or V Shore Frame system from our online store.

Alternatively, if you need scaffolding formwork in Sydney, Melbourne, Brisbane, and Perth, you can contact us to get access to a wide range of products that can aid you in your construction project.